Mineral processing Wikipedia

In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores.

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores.

TGS 210 E MiniMax This is a 3 HP 220V electric direct driven hammer mill. This hammer mill has both a grinding and a shredding function. Shredding of any dry or green ...

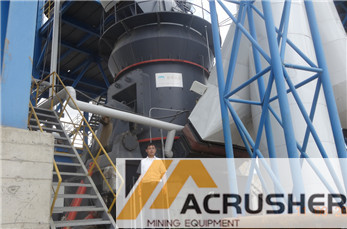

Crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

Amalgamation has been used for thousands of years to recover small sized or fine gold. Historically, it was used in many operations to increase gold recovery.

how fine to grind gold ore. How Fine To Grind Gold Ore. stutenroth fine grind impact mill. Stutenroth Fine Grind Impact MillFine impact mills and classifier mills ...

Flotation Separation Valuable mineral in an ore such as chalcopyrite ore can be separated from each other and from worthless gauge minerals by the froth ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

Ultra fine grinding mills for gold ore. Grinding mills, Ball Mill, Vertical Roller Mill for Ultra fine grinding mills for gold ore. Project List; MTM130X seriesx ...

Minerals Processing Solutions. 2 3 ... media optimized for your ore 5 0 Ore sample Ball mill Stirred ... Fine grinding is playing a growing role in the benefi ...

United Nuclear : What''s New Radiation and Nuclear Chemistry Tools And Equipment Electronic Electrical General Science General Interest Neodymium Magnets Gift ...

Located near Salt Lake City, Ut, US, Bingham Canyon celebrated its 100th anniversary in June 2003. The Bingham Canyon mine, Copperton concentrator and .

Feed material preparation is quite critical to successful pelletizing. Proper premixing of feed when there is a multiplicity of materials and especially...

HRC™ high pressure grinding rolls (HPGR) The HRC™ takes HPGR technology to the next level by providing a simple yet robust design that maximizes efficiency ...

Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or cyanidation.

Korean product list of healthy recipes, breakfast recipes, easy recipes from Favorite Food manufacturers, suppliers at buyKOREA

As a professional and experienced manufacturer of mobile crusher,jaw crusher,cone crusher,impact crusher,ball mill,super fine mill and vertical mill, not only ...

MINING . This page primarily focuses on metallurgical mining, though many of the terms, processes, and concepts are the same within the nonmetallurgical extraction ...

fine grinding gold ore. Processing of Magnetite Iron Ores Comparing Grinding Options. crushing and stirred milling for fine grinding, has provided opportunities to ...

A typical type of fine grinder is the ball mill. ... Autogenous or autogenic mills are socalled due to the selfgrinding of the ore: ... Like ball mills, grinding ...

Mills in Derbyshire and the Peak District including cotton, corn, paper, lead smelting, fulling, black marble, comb, bump and saw mills

Ultra Fine Grinding A Practical Alternative to ... exploit natural fracture planes in the ore allowing ... Ultra fine grinding mills have been in use ...

Use of Iron Ore Pellets in Blast Furnace Burden Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 ...

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its .

WhatsApp)

WhatsApp)